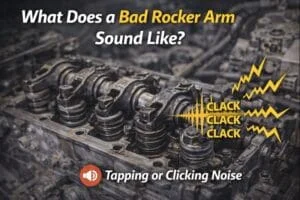

Unusual ticking or tapping noises from an engine are often early warning signs of valvetrain trouble. These sounds may start quietly and become more noticeable with increased engine speed, making them easy to dismiss at first. However, when the noise sharpens during acceleration, it frequently points to components that control valve movement rather than external accessories.

Rocker arms play a critical role in transferring camshaft motion to the valves, and when they wear, loosen, or lose proper lubrication, they can produce a distinct metallic ticking sound. Because the engine may continue to run normally for some time, the issue is often misjudged as minor until performance or reliability begins to suffer.

The explanation below focuses on the characteristic noises associated with a failing rocker arm, why those sounds develop, how the problem can be identified safely, and what steps help prevent further engine damage. The goal is to replace uncertainty with a clear understanding of what the noise means and how urgently it should be addressed.

What a Rocker Arm Does

Before we talk about the sound, it helps to understand what a rocker arm does. Simply put, a rocker arm is a small lever inside the engine that transfers motion from the camshaft to the valves.

This opens and closes them at precise intervals, allowing air and fuel to enter the combustion chamber and exhaust gases to exit.

Think of it as a tiny, yet critical, mechanical translator. If it works correctly, you’ll never hear it. But when something goes wrong, it announces itself loud and clear.

Recognizing the Typical Sounds of a Failing Rocker Arm

The most common auditory warning is metallic ticking or tapping. Unlike other engine noises, this one has a clear rhythm that often matches the engine RPM. There are several characteristics:

- Soft at idle, louder under acceleration

- Consistent pattern, not random clunks

- High-pitched, almost like a small hammer hitting metal

- Sometimes accompanied by a faint vibration inside the engine bay

It’s easy to mistake this for valve noise, lifter issues, or even fuel injector sounds. That’s why listening carefully, and in different conditions, is essential.

Why Rocker Arms Fail

Rocker arms are made of strong materials, but they experience constant stress. Over time, wear or damage can lead to problems. Common causes include:

- Insufficient lubrication – oil starvation can accelerate wear

- Excessive engine mileage – simple metal fatigue

- Improper valve adjustment – too tight or too loose, creating stress

- Hydraulic lifter issues – can transfer irregular motion to the rocker arm

- Debris or contamination – particles in the oil causing scratches or grooves

How the Sound Changes with Driving

- At idle: soft, intermittent taps

- During light acceleration: slightly faster ticking

- Under heavy load: louder, sharper, sometimes resembling a nail on metal

- After long drives: occasionally louder due to heat expansion and thinner oil

These changes help differentiate a rocker arm issue from other engine noises, which may remain steady or only appear under specific conditions.

Rocker Arm vs. Other Engine Noises

A lot of people confuse rocker arm noises with other common sounds. Here is the difference between them:

- Valve lifters: often high-pitched, sometimes adjustable with engine RPM

- Fuel injectors: more of a rhythmic click, usually quiet and steady

- Exhaust leaks: louder, hissing, or popping noises

- Timing chain: deeper, more pronounced metallic rattle, especially on cold start

Diagnosing the Problem Safely

You don’t need to take the engine apart immediately.

- Listen with the hood open – a simple mechanic’s stethoscope or even a long screwdriver against the engine block helps pinpoint the source

- Check oil level and condition – low or dirty oil often exacerbates ticking

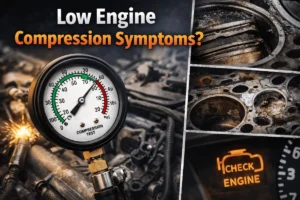

- Observe performance – misfires, rough idle, or reduced power can accompany rocker arm problems

- Look for visual signs – oil leaks around the rocker covers, unusual wear marks, or damaged pushrods

Always start with these non-invasive checks before assuming a full teardown is needed.

Temporary Fixes I’ve Tried

There are small steps that can help mitigate damage until a proper repair:

- High-quality engine oil – sometimes improved lubrication reduces ticking

- Adjusting valve lash (if applicable) – only on engines designed for this

- Regular maintenance – frequent oil changes prevent worsening

These measures won’t fix a severely worn rocker arm but can reduce risk and noise temporarily.

When You Need Professional Help

In our experience, once the ticking persists and oil changes don’t help, it’s time to consult a professional. A technician can:

- Inspect and replace worn rocker arms

- Check pushrods, lifters, and valve springs

- Assess camshaft condition

- Ensure proper torque and clearance

Trying to drive extensively with a bad rocker arm can lead to valve damage, camshaft scoring, and expensive repairs.

Cost Considerations

Rocker arm replacement costs vary widely depending on engine type, labor rates, and the number of components involved. From personal research:

- Parts alone: $50–$300 per rocker arm

- Labor: $150–$500 depending on complexity

- Full rocker assembly replacement: can exceed $1,000 on some engines

Waiting until the engine suffers collateral damage multiplies the expense.

Preventing Rocker Arm Issues

From my own maintenance habits, prevention is mostly about care and routine:

- Regular oil changes – clean, high-quality oil keeps all moving parts healthy

- Proper oil levels – never ignore low oil warnings

- Monitor unusual sounds – early detection prevents cascading damage

- Routine inspections – especially on high-mileage vehicles

Engines go hundreds of thousands of miles without major rocker arm issues simply because they were well-maintained.

Final Thoughts

A ticking sound in the engine can be alarming, but not all noises are catastrophic. Recognizing the characteristics of a bad rocker arm, understanding why it happens, and knowing when to get professional help are key to keeping your engine healthy.

The most important thing is listening carefully and acting early. Waiting too long can turn a simple repair into an expensive nightmare. Rocker arms are small, but they play a huge role in engine longevity.

Paying attention to their warning signs has saved me countless headaches over the years.