Low-side pressure readings play a critical role in diagnosing automotive air conditioning performance. When the low-side pressure runs higher than normal, cooling efficiency often drops even though the system appears to be operating.

The compressor may engage, refrigerant may be present, and no obvious mechanical noise may be heard—yet cabin temperatures remain disappointing.

This type of issue is common because AC systems rarely fail in a single, dramatic way. Instead, pressure readings drift outside their normal range due to airflow problems, refrigerant imbalance, or internal restrictions. Interpreting those numbers correctly is essential to avoid misdiagnosis and unnecessary component replacement.

The explanation that follows focuses on what high low-side pressure actually indicates, how the low-pressure side functions within the AC system, the most common conditions that cause pressure to rise, and how technicians logically narrow down the root cause before repairs are made.

Understanding What the Low Side of the AC System Does

Before diagnosing anything, you need to understand the role of the low side.

The low side of the AC system is where refrigerant returns to the compressor after absorbing heat from the cabin. This side operates at lower pressure because the refrigerant is supposed to be cool and expanded at this stage.

When everything works correctly:

- refrigerant flows smoothly

- pressure stays within a specific range

- the evaporator absorbs heat efficiently

- cold air flows from the vents

When low-side pressure climbs too high, it usually means heat isn’t being removed properly or refrigerant isn’t behaving the way it should.

Why High Low-Side Pressure Is a Problem

High pressure on the low side almost always leads to poor cooling.

Instead of absorbing heat efficiently, the system struggles to create a temperature difference. The result is:

- weak cooling

- longer compressor run time

- strain on components

- increased wear

The system is still “working,” but not doing its job effectively.

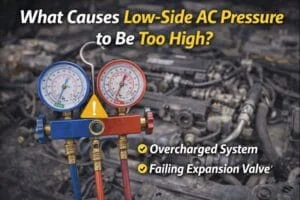

Overcharged AC System: One of the Most Common Causes

This is the first thing to check—and for good reason.

Adding too much refrigerant raises pressure throughout the system, including the low side. Many people assume “more refrigerant means colder air,” but that’s not how AC systems work.

When overcharged:

- refrigerant doesn’t fully expand

- heat transfer efficiency drops

- pressure stays elevated

- cooling performance suffers

This often happens when refrigerant is added without gauges or proper measurement.

Insufficient Heat Removal at the Condenser

The condenser’s job is to release heat absorbed from inside the vehicle.

If heat can’t escape properly, pressure backs up through the system—including the low side.

Common reasons include:

- blocked airflow from debris

- bent or damaged fins

- inoperative cooling fans

- poor airflow at low speeds

We’ve seen a single failed fan cause pressure readings that confused everyone until airflow was restored.

Compressor Issues That Affect Pressure Balance

A compressor doesn’t just compress—it regulates flow.

When internal wear or valve damage occurs, the compressor may fail to create the proper pressure difference between the high and low sides.

This can result in:

- elevated low-side readings

- reduced cooling output

- inconsistent system behavior

The system may look “charged,” but it’s not functioning efficiently.

Expansion Valve or Orifice Tube Problems

The expansion device controls how much refrigerant enters the evaporator.

If it sticks open or fails to regulate flow properly:

- too much refrigerant enters the evaporator

- pressure rises on the low side

- refrigerant doesn’t fully evaporate

- cooling weakens

This is a subtle failure that often requires pressure comparison and temperature checks to identify.

Moisture or Air Contamination Inside the System

This is something many people overlook.

If moisture or air enters the system:

- refrigerant behavior becomes unpredictable

- pressure readings rise abnormally

- cooling efficiency drops

Moisture can freeze or boil in the wrong places, disrupting pressure balance. Air contamination reduces heat transfer efficiency and raises system pressure.

This usually happens when:

- the system was opened improperly

- evacuation wasn’t done thoroughly

- DIY repairs skipped critical steps

Evaporator Problems That Trap Heat

The evaporator must absorb heat efficiently.

If airflow through the evaporator is restricted, heat exchange suffers, leading to higher pressure on the low side.

Possible causes include:

- clogged cabin air filter

- debris buildup

- blower motor issues

- evaporator icing or blockage

We’ve seen a simple cabin filter cause hours of confusion before someone checked it.

Incorrect Refrigerant Type or Oil

Modern AC systems are very specific.

Using the wrong refrigerant or incorrect oil can change:

- pressure behavior

- heat transfer efficiency

- compressor performance

Even small deviations from specifications can create pressure irregularities that mimic mechanical failures.

Faulty Pressure Sensors or Gauge Readings

Sometimes the system is fine—the data isn’t.

Faulty sensors, damaged service ports, or inaccurate gauges can show higher-than-actual readings.

That’s why always check:

- verify readings with known-good equipment

- compare pressure with temperature charts

- confirm sensor behavior electronically when possible

Never diagnose based on a single reading alone.

Ambient Temperature and Its Effect on Readings

Environmental conditions matter more than most people realize.

On very hot days:

- pressures naturally rise

- readings must be interpreted carefully

- comparing to normal ranges without context leads to misdiagnosis

High low-side pressure on a hot day may still be abnormal—but you need temperature-corrected expectations.

Symptoms That Often Accompany High Low-Side Pressure

In my experience, these signs often show up together:

- weak or inconsistent cooling

- compressor running continuously

- warmer air at idle

- system working better at higher speeds

- poor performance in traffic

These clues help narrow the cause quickly.

How to Approach Diagnosing This Issue

When you see elevated low-side pressure, follow a simple process:

- Check refrigerant level accurately

- Verify condenser airflow

- Inspect fans and shrouds

- Compare high-side readings

- Check temperature differences

- Evaluate expansion device behavior

- Confirm sensor accuracy

Skipping steps leads to wasted time and unnecessary part replacement.

Why Guessing Makes AC Problems Worse

AC systems are sensitive. Guessing often results in:

- overcharging

- contamination

- component damage

- expensive repairs

We’ve seen perfectly repairable systems ruined by repeated “top-offs” without diagnosis.

When Professional Help Makes Sense

Some AC problems require:

- refrigerant recovery equipment

- vacuum testing

- leak detection tools

- internal component inspection

If pressure readings don’t respond logically to corrections, professional diagnostics save money in the long run.

Preventing High Low-Side Pressure Problems

From my own experience, prevention comes down to:

- correct refrigerant handling

- proper evacuation procedures

- maintaining airflow components

- addressing small issues early

- avoiding DIY shortcuts

AC systems reward precision and punish guesswork.

Final Thoughts

When low-side AC pressure is too high, the system is telling you something important—but not always obvious. It’s rarely a single cause and almost never something to ignore.

Understanding how pressure relates to airflow, heat transfer, and refrigerant behavior turns confusion into clarity. Once you stop chasing guesses and start following the system’s logic, the solution usually reveals itself.

If your AC isn’t cooling the way it should and the low-side pressure looks wrong, take a breath, gather good information, and approach the problem methodically. Your system—and your wallet—will thank you.