It’s a crisp morning and you’re heading to work in your 2011 Dodge Charger R/T. The HEMI V8 usually fires up with a growl, but today, there’s an odd tapping sound under the hood. It’s subtle at first but gets louder as the engine warms up. Performance feels a little sluggish, too, and now your oil light flickers. Something’s definitely not right.

These early signs can often be traced back to a problem deep within your engine—specifically, your lifters.

Lifters aren’t the flashiest components in an engine, but they play a major role in keeping everything running smoothly. When they start to fail, they can cause noticeable issues and, if ignored, serious damage.

This guide walks you through what lifters are, why they matter, how to tell when they’re going bad, and what to do if you suspect trouble. Let’s get into it.

What Are Engine Lifters?

Lifters—also called hydraulic tappets—are part of the valve train in your engine. Their main job is to transfer motion from the camshaft to the pushrods (or directly to the valves in some engines). This motion is what opens and closes the engine’s intake and exhaust valves.

There are two main types of lifters:

- Hydraulic lifters: The most common type in modern engines. They self-adjust using engine oil pressure, keeping the valve lash (gap) optimal.

- Solid lifters: Typically used in high-performance or older engines. These require manual adjustment.

Hydraulic lifters are quieter and maintenance-free—until they start to fail.

What Causes a Lifter to Go Bad?

A bad lifter isn’t always caused by a single issue. Several factors can wear them down or cause them to malfunction:

- Dirty or old engine oil

- Low oil pressure

- Sludge buildup

- Excessive engine wear or heat

- High mileage

- Neglected oil changes

Because lifters rely on oil pressure to function properly, any problem with lubrication can lead to lifter damage.

Common Symptoms of a Bad Lifter

Spotting lifter problems early can save you from a full engine rebuild. Let’s break down the most common symptoms in simple terms.

1. Ticking or Tapping Sound from the Engine

This is often the first sign. A bad lifter can make a distinct ticking or tapping noise, especially when the engine is cold. The sound usually comes from the top of the engine and may quiet down once the oil warms up—but not always.

Why it happens: The lifter isn’t holding oil pressure, causing metal-to-metal contact.

2. Misfire or Rough Idle

A failing lifter can prevent a valve from opening properly, which can throw off the air-fuel mixture and lead to engine misfires. You might notice the engine shaking at idle or hesitation when accelerating.

Tip: A diagnostic scan may show a misfire code (like P0300), even though the issue is mechanical.

3. Check Engine Light

Modern vehicles monitor performance closely. If a bad lifter causes valve timing issues or misfires, the check engine light will likely come on. A scan tool can point you toward the affected cylinder or system.

4. Loss of Power

If a valve doesn’t open fully, that cylinder can’t produce full power. As a result, you may notice a drop in engine performance, especially under load (like going uphill or accelerating).

5. Unusual Engine Noise Under Load

Aside from tapping at idle, you might hear louder clacking sounds when the engine is working harder. This happens because lifter failure worsens under stress, where oil pressure changes rapidly.

6. Oil Warning Light or Low Oil Pressure

Since hydraulic lifters rely on oil pressure, problems in the lubrication system can either cause lifter damage or be a result of it. Keep an eye on oil pressure gauges or warning lights.

7. Valve Train Damage (in advanced cases)

If the issue goes unnoticed for too long, the lifter can damage the camshaft, pushrods, or even bend valves. At this stage, the repairs become much more extensive and expensive.

Diagnosing a Bad Lifter

If you suspect a lifter problem, here’s how mechanics usually go about confirming it:

Step 1: Listen Closely

A mechanic will use a mechanic’s stethoscope or even a long screwdriver to pinpoint where the ticking is coming from. The top of the engine usually indicates valve train noise.

Step 2: Oil Condition and Level

Next, they’ll check the oil level and look for signs of sludge, contamination, or breakdown. Dark, dirty oil can clog lifters or make them stick.

Step 3: Scan for Engine Codes

A scan tool can reveal misfires, timing problems, or performance issues tied to lifter failure.

Step 4: Compression or Leakdown Test

These tests can show if a valve isn’t sealing properly—often the result of a lifter not opening or closing a valve fully.

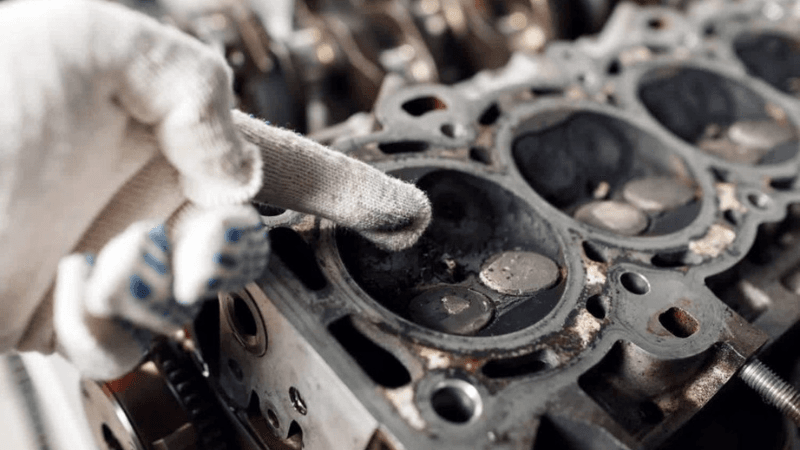

Step 5: Visual Inspection

For serious or confirmed issues, the valve cover and possibly the intake manifold may be removed to physically inspect the lifters and related components.

Can You Drive with a Bad Lifter?

Technically, yes—for a little while. But it’s not recommended.

A mildly faulty lifter might only cause noise at first, but it can quickly lead to:

- Pushrod damage

- Camshaft wear

- Valve timing issues

- Complete engine failure

If you’re hearing a ticking sound or notice performance issues, it’s best to get the car checked right away. Ignoring it can turn a $300 repair into a $3,000 problem.

Repair Options: Fix or Replace?

The approach depends on the severity of the issue.

Option 1: Try a Lifter Cleaning Additive

If the lifter is sticking due to sludge or varnish, a cleaning additive like Sea Foam or Marvel Mystery Oil might help. Add it to the oil and drive gently for a few hundred miles, then do an oil change.

When it helps: Only in very early stages of lifter noise. Won’t fix mechanical wear.

Option 2: Replace the Lifters

This is the most common solution. Replacing lifters involves:

- Removing the valve covers

- Possibly removing the intake manifold

- Pulling the pushrods

- Replacing the faulty lifter(s)

Costs can vary:

| Vehicle Type | Lifter Replacement Cost |

| 4-cylinder engines | $400 – $800 |

| V6 engines | $600 – $1,200 |

| V8 engines (e.g., HEMI) | $1,000 – $2,500 |

The price depends heavily on labor and engine layout. In some engines (like GM’s AFM-equipped V8s), the heads must be removed—adding time and complexity.

Special Note on GM’s AFM Engines

GM’s Active Fuel Management (AFM) system is notorious for lifter failures. These engines (like the 5.3L and 6.0L V8s) use special lifters to deactivate cylinders under light load.

When AFM lifters fail, the only real fix is to:

- Replace the bad lifters

- Disable AFM with a tune or delete kit

- Install a non-AFM camshaft (optional but common)

These repairs can run from $1,500 to $3,500+.

Preventing Lifter Failure

The best way to avoid lifter problems is with simple, consistent maintenance:

1. Regular Oil Changes

Use high-quality oil and change it at the recommended intervals. Sludge and dirty oil are a lifter’s worst enemy.

2. Use the Right Oil

Always use the manufacturer-recommended viscosity. Too thick or too thin can affect oil pressure.

3. Avoid Long Idle Periods

Modern engines hate prolonged idling. It can reduce oil pressure and cause lifters to run dry, especially when cold.

4. Don’t Ignore Noises

A small ticking sound might seem harmless, but catching it early could prevent a full engine teardown later.

When Is It Time to Replace the Whole Engine?

If you’ve caught the issue late and there’s camshaft damage, metal in the oil, or multiple lifters failed, it may not be worth trying to fix piece by piece.

In cases like:

- High-mileage vehicles

- Excessive labor estimates

- Catastrophic valve train damage

…it might make more financial sense to replace or rebuild the engine.

Lifter issues are sneaky. They start small, often as a harmless tick, and can grow into something much more serious if left unchecked. The good news is that with attention to the early signs and proper maintenance, you can avoid major problems.

Here’s a quick recap:

- Symptoms include ticking noises, misfires, check engine lights, and rough performance

- Early diagnosis can save thousands in repairs

- Costs range from a few hundred to over $2,000 depending on vehicle and severity

- Prevention starts with oil changes and not ignoring warning signs

If you think your lifter is going bad, don’t panic—but don’t wait either. Have a trusted mechanic inspect the issue so you can get back on the road with peace of mind.