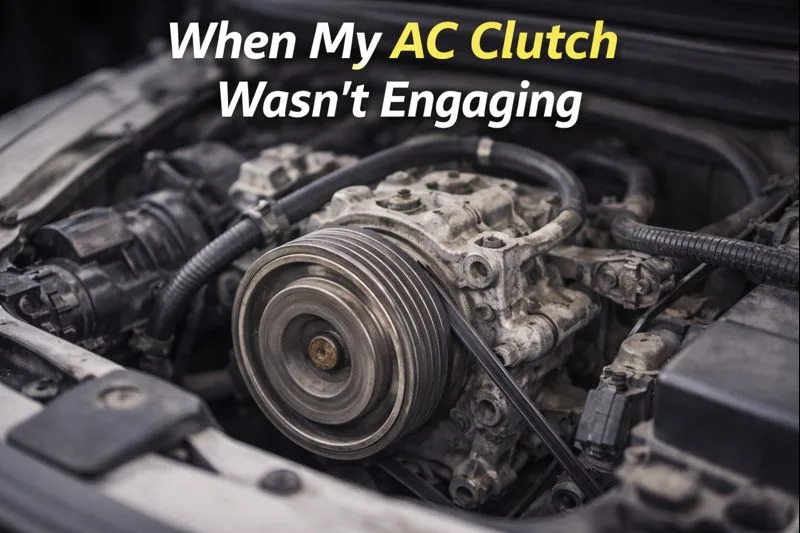

When an air conditioning system stops cooling, the compressor clutch is one of the first components technicians evaluate. The clutch is responsible for engaging the compressor when cooling is requested, and if it fails to engage, refrigerant cannot circulate—even if the rest of the system appears intact. This can leave the impression that the AC is running normally while warm air continues to blow from the vents.

An AC clutch that will not engage can be caused by a wide range of issues, from simple electrical interruptions to pressure-related safeguards or mechanical wear. Because the symptoms often look similar regardless of the cause, incorrect assumptions can lead to unnecessary part replacement or missed repairs.

What follows explains how the AC clutch functions, why engagement fails, which causes are most common, and how the problem is typically identified in a logical order. Understanding these basics makes it easier to recognize whether the issue is minor, maintenance-related, or something that requires deeper inspection before repairs begin.

What the AC Clutch Actually Does

Before I ever had this problem, I had no idea what the AC clutch even was.

The AC clutch is a mechanical link between your engine and the air conditioning compressor. When you turn on the AC, the clutch engages, locking the compressor to the engine so it can start circulating refrigerant. When cooling isn’t needed, the clutch disengages and lets the compressor rest.

This on-off behavior protects the system and improves efficiency. When the clutch doesn’t engage, the compressor never turns on, which means no cold air—no matter how long you wait.

Once I understood that, the problem stopped feeling mysterious and started feeling logical.

How I Knew the AC Clutch Wasn’t Engaging

The signs were subtle at first, then obvious.

Here’s what I noticed:

- The air stayed warm no matter the setting

- No clicking sound when switching the AC on

- The outer pulley spun, but the center section stayed still

- Engine idle didn’t change when AC was turned on

That missing click is important. Under normal conditions, you can hear or feel the clutch engage. When it doesn’t happen, it’s the system telling you something isn’t right.

Why an AC Clutch Fails to Engage

This is where most people panic, but I learned quickly that the cause isn’t always severe.

Low Refrigerant Level

This was the biggest surprise for me.

Modern AC systems are designed to protect themselves. If the refrigerant level drops too low, the system prevents the clutch from engaging to avoid internal damage.

That means:

- No refrigerant doesn’t just reduce cooling

- It can stop the compressor from turning on entirely

In my case, a slow leak over time caused the system to shut itself down quietly.

Electrical Issues

The AC clutch relies on electricity to function. If that power is interrupted, nothing happens.

Common electrical causes include:

- Blown fuse

- Faulty relay

- Broken wiring

- Poor ground connection

I found a blown fuse that looked perfectly fine until I tested it. That one tiny component stopped the entire system.

Faulty Pressure Switch

Pressure sensors monitor the system and act as safety guards.

If pressure is:

- Too low

- Too high

the switch prevents the clutch from engaging. These sensors can fail on their own, even if the rest of the system is healthy.

A bad sensor can trick the system into thinking something’s wrong when it isn’t.

Worn or Damaged Clutch

Sometimes the problem is mechanical.

Over time, the clutch surface wears down, increasing the gap between components. If the gap gets too large, the magnetic force isn’t strong enough to pull the clutch in.

This often shows up as:

- Intermittent cooling

- AC working only when cold

- Clicking sounds without engagement

This type of failure tends to worsen gradually, not suddenly.

Compressor Issues

This is the cause everyone fears, but it’s not always the case.

If the compressor is seized or internally damaged, the system may prevent engagement to avoid further harm. In some cases, the clutch itself is fine, but the compressor can’t turn.

This usually comes with other symptoms like noise, belt issues, or prior cooling problems.

Why the System Is Designed This Way

At first, it felt frustrating that the AC would simply stop working without warning.

But the more I learned, the more I appreciated the design. The system is built to:

- Prevent expensive damage

- Protect internal components

- Avoid dangerous pressure conditions

When the clutch doesn’t engage, it’s often doing exactly what it was designed to do.

What I Checked First (And What I Recommend)

Instead of guessing, I followed a simple order.

Step 1: Visual Inspection

I checked:

- Belt condition

- Pulley movement

- Wiring around the compressor

Anything loose, cracked, or damaged can give you instant answers.

Step 2: Fuse and Relay Check

This is fast and inexpensive.

I swapped the relay with a matching one in the fuse box. When the clutch suddenly engaged, I had my answer.

Step 3: Refrigerant Pressure

I used a basic gauge set, nothing fancy.

Low pressure doesn’t always mean “empty,” but it does mean the system won’t engage. This step alone solves many cases.

Step 4: Electrical Signal at the Clutch

With the AC on, the clutch should receive power.

No voltage means:

- Sensor issue

- Wiring problem

- Control module decision

Voltage present but no engagement usually points to the clutch itself.

Why Jumping the Clutch Is Risky

I’ve seen plenty of advice telling people to jump power directly to the clutch.

Yes, it can make it engage—but it bypasses all safety systems.

Doing this can:

- Damage the compressor

- Cause pressure spikes

- Mask serious issues

I learned that this should only be used briefly for testing, not as a fix.

How Driving Habits Affect the AC Clutch

Something I didn’t expect was how usage patterns matter.

AC systems that:

- Sit unused for long periods

- Run constantly at max settings

- Operate with low refrigerant

are more likely to develop clutch issues. Occasional use year-round helps keep components healthy.

Repair Options and What They Mean

Once I identified the cause, I had choices.

Refrigerant Service

If the system is low, proper evacuation and recharge is essential. Topping off without fixing leaks is temporary.

Electrical Repair

Fuses, relays, and wiring repairs are usually straightforward and affordable when caught early.

Clutch Replacement

Some compressors allow clutch replacement without changing the entire unit. This can save a significant amount of money.

Full Compressor Replacement

This is the most expensive route but sometimes unavoidable if internal damage exists.

The key is accurate diagnosis before replacement, not after.

What I Wish I Had Known Earlier

I used to think AC problems were either simple or catastrophic. The truth sits somewhere in between.

What I learned:

- The system is protective, not fragile

- Silence often means prevention, not failure

- Most problems leave clues if you look carefully

Understanding that saved me from unnecessary repairs.

When It’s Time to Call a Professional

I handle basic diagnostics myself, but I stop when:

- Pressure readings don’t make sense

- Electrical signals conflict

- Internal damage is suspected

A qualified technician with proper tools can see things I can’t—and that’s okay.

Final Thoughts

An AC clutch that won’t engage can feel intimidating, especially when the heat is unbearable and answers aren’t obvious. But once you understand how the system thinks and protects itself, the problem becomes far less mysterious.

I’ve been through the confusion, the guessing, and the temptation to replace parts blindly. What worked best was slowing down, learning the system step by step, and respecting the signals the car was giving me.

If your AC clutch isn’t engaging, don’t panic. There’s a reason—and with the right approach, you’ll find it.