A seat belt that refuses to extend is more than an inconvenience—it immediately turns a usable vehicle into one that shouldn’t be driven. Because seat belts are designed to lock under specific conditions, a jammed belt often leaves drivers unsure whether they’re dealing with a minor issue or a built-in safety response doing its job.

Modern seat belt systems use inertia-based and tension-sensitive locking mechanisms. These systems are meant to prevent movement during sudden stops or impacts, but they can also activate under everyday conditions such as sharp angles, contamination inside the retractor, or internal wear. That’s why a belt can suddenly feel stuck even when the car hasn’t been in an accident.

The explanation that follows breaks down how seat belt retractors work, the most common reasons a belt won’t pull out, which checks can be done safely, and when replacement is the only responsible option. The focus is on restoring proper function without compromising safety or overlooking a critical restraint component.

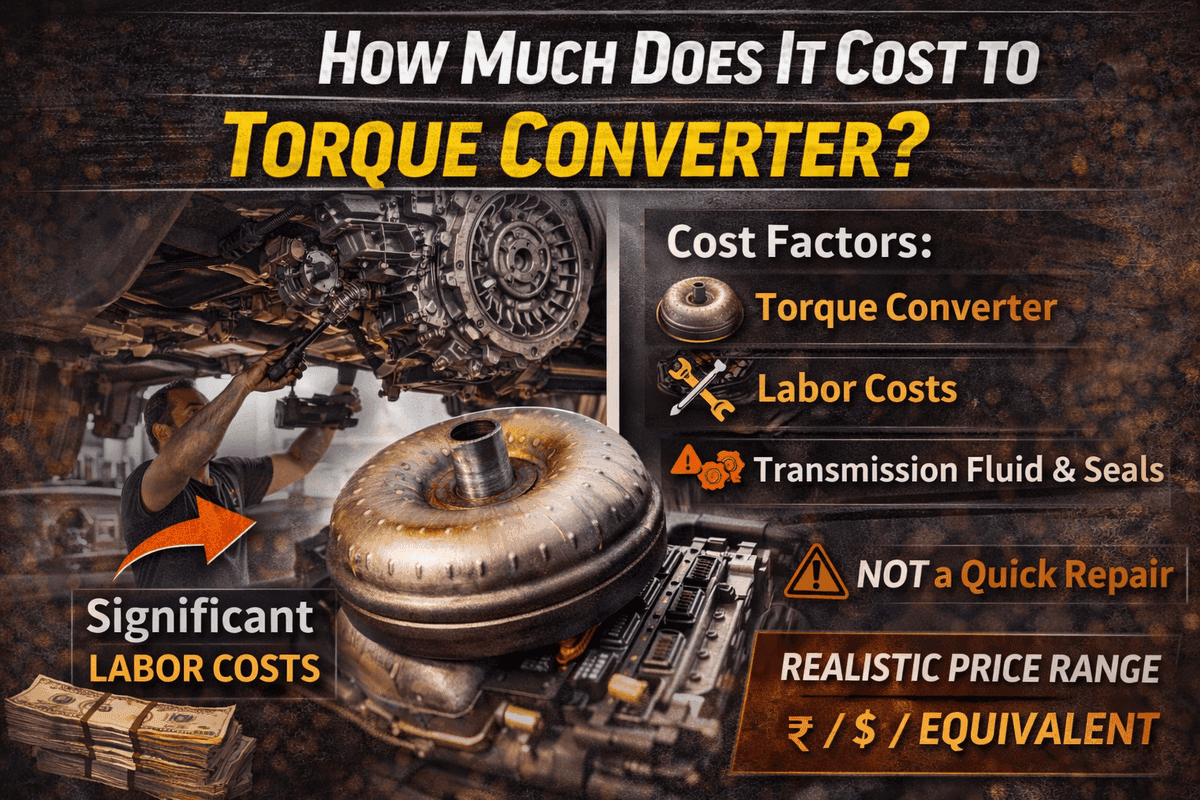

First, What a Torque Converter Actually Does (Quick and Simple)

Before talking about cost, it helps to understand what this part does.

In an automatic car:

- The torque converter connects the engine to the transmission

- It replaces a manual clutch

- It allows the car to stop without stalling

- It multiplies engine force when accelerating

It’s a sealed, fluid-filled component that lives inside the transmission bell housing. That location is the main reason replacement gets expensive.

Why Replacing a Torque Converter Costs So Much

Here’s the key thing most people don’t realize:

👉 The torque converter itself is not the expensive part — the labor is.

To replace it:

- The transmission must be removed

- The converter is accessed

- Everything is reinstalled and tested

That’s a big job, even on simple cars.

Average Cost to Replace a Torque Converter (Realistic Range)

Let’s talk numbers in a clear, honest way.

In most real-world situations, torque converter replacement costs fall between:

₹ / $ / equivalent:

- Lower end: when labor is cheaper and the vehicle is simple

- Higher end: when labor is intensive or the vehicle is complex

In general terms (globally):

- Parts: moderate

- Labor: high

- Total cost: often similar to major transmission work

This is why people are often shocked when they hear the estimate.

Breaking the Cost Down — Where the Money Goes

I find it easier to understand costs when they’re broken into pieces.

1. Cost of the Torque Converter Itself

The torque converter is a precision component, but it’s not always outrageous in price.

Typical factors affecting its price:

- Vehicle type

- Engine size

- Transmission design

- New vs remanufactured

Prices vary widely, but the converter alone is often not the largest part of the bill.

2. Labor Cost (The Biggest Expense)

This is where most of the money goes.

Replacing a torque converter requires:

- Supporting the engine

- Disconnecting the transmission

- Removing driveshafts or axles

- Lowering the transmission

- Reinstalling and aligning everything

Labor time can range from:

- Several hours on simple vehicles

- Much longer on complex or tightly packed cars

Labor rates vary by location, which is why quotes can look very different.

3. Transmission Fluid and Related Parts

Once the transmission is removed:

- Fluid must be drained

- Fresh fluid is required

- Seals and gaskets are often replaced

These costs add up but are necessary. Reusing old fluid is not an option.

4. “While You’re in There” Costs

This is where decisions matter.

Because the transmission is already out, shops often recommend:

- Replacing worn seals

- Addressing known weak points

- Preventive maintenance

This can raise the total cost—but sometimes saves money later.

Why the Same Repair Can Cost Very Different Amounts

You might get two estimates that are miles apart. That’s normal.

Reasons include:

- Labor rate differences

- Vehicle layout

- Front-wheel vs rear-wheel drive

- Transmission size

- Shop experience

A small sedan and a large SUV are completely different jobs.

Front-Wheel Drive vs Rear-Wheel Drive Cost Difference

This is a big factor many people overlook.

Front-Wheel Drive

- Transmission is often tightly packed

- More components must be removed

- Labor time is usually higher

Rear-Wheel Drive

- Transmission access is often easier

- Less disassembly required

- Labor can be slightly lower

This difference alone can change the final cost significantly.

Signs That the Torque Converter Actually Needs Replacement

Before spending money, it’s important to be sure.

Common symptoms include:

- Shuddering at low speeds

- Slipping during acceleration

- Delayed engagement

- Overheating transmission

- Unusual vibration

Not all transmission issues are torque converter problems, which is why diagnosis matters.

Why Misdiagnosis Can Get Very Expensive

This is something I’ve learned the hard way.

Torque converter symptoms can feel similar to:

- Transmission internal wear

- Fluid problems

- Software or control issues

Replacing a converter won’t fix the problem if it isn’t the root cause.

Always confirm before committing.

Can You Replace Only the Torque Converter?

Sometimes, yes.

If:

- The transmission itself is healthy

- No internal damage is present

- The issue is isolated

Then replacing just the converter can make sense.

But in some cases:

- Converter failure damages the transmission

- Metal debris spreads through the system

That’s when costs rise quickly.

Torque Converter Replacement vs Transmission Replacement

This is an important comparison.

Torque Converter Only

- Lower cost

- Less invasive

- Worth it if transmission is solid

Full Transmission Replacement

- Much higher cost

- Necessary if internal damage exists

- Often recommended if mileage is high

This decision depends on diagnosis, not guesswork.

Is It Worth Replacing the Torque Converter?

This is the question everyone asks me.

I look at:

- Vehicle value

- Mileage

- Overall condition

- How long I plan to keep the car

If the car is otherwise solid, replacing the converter can make sense.

If the car has multiple major issues, it may not.

Why Some Shops Recommend a Full Rebuild Instead

From the shop’s perspective:

- Labor overlap is significant

- Risk of repeat failure exists

- Warranty considerations matter

Sometimes they’re being cautious—not greedy. But it’s okay to ask questions.

New vs Remanufactured Torque Converters

You’ll usually have options.

New

- Higher cost

- Factory specs

- Longer expected life

Remanufactured

- Lower cost

- Rebuilt to standards

- Commonly used

Both can be reliable if sourced properly.

How Long the Repair Takes

Most torque converter replacements take:

- At least one full day

- Sometimes longer if complications arise

It’s not a quick in-and-out repair.

Can You Drive With a Bad Torque Converter?

Short answer: not recommended.

Driving with a failing converter can:

- Damage the transmission

- Increase repair cost

- Leave you stranded

What starts as a converter problem can turn into a full transmission failure.

Why This Repair Feels So Overwhelming

It’s not just the money.

It’s because:

- The part is hidden

- The repair is complex

- The consequences feel big

Understanding the process makes it less intimidating.

How I Decide If a Quote Is Fair

Here’s my personal checklist:

- Does the shop explain the diagnosis clearly?

- Are labor hours reasonable for the vehicle type?

- Are fluid and seals included?

- Is there a warranty?

Transparency matters more than the lowest price.

Ways to Reduce the Cost (Without Cutting Corners)

Some smart approaches include:

- Getting a second opinion

- Asking about remanufactured parts

- Combining repairs efficiently

- Avoiding unnecessary add-ons

Cheap repairs cost more later.

What Happens If You Delay the Repair

Delaying can:

- Worsen internal damage

- Increase heat and wear

- Turn a manageable repair into a major one

Timing matters a lot with transmission issues.

Common Myths About Torque Converter Replacement

Let’s clear a few up.

- “It’s always the transmission” — Not always

- “The part itself is insanely expensive” — Usually not

- “It’s never worth fixing” — Depends on the car

- “All shops charge the same” — They don’t

Understanding removes fear.

My Honest Advice If You’re Facing This Repair

If you’re staring at a torque converter estimate right now, take a breath.

Ask questions.

Understand the diagnosis.

Look at the whole picture—not just the number.

I’ve learned that torque converter replacement is expensive because it’s labor-heavy, not because shops are trying to take advantage of you. When done correctly, it can restore smooth operation and extend the life of the vehicle significantly.

Final Thoughts — Why Knowing the Cost Changes Everything

Replacing a torque converter isn’t cheap, but it also isn’t mysterious once you understand what’s involved. The cost reflects the complexity of the job, the skill required, and the amount of work needed to access that one critical component.

I’ve found that once people understand where the money goes, the decision becomes clearer—whether that decision is to repair, replace, or move on. Knowledge gives you control, and control makes even expensive repairs easier to face.